Scan to BIM Workflow: From Reality Capture to Intelligent Digital Building Models

The construction industry is no longer driven only by drawings and site assumptions. Modern projects demand precision, speed, and reliable data. As buildings grow more complex, traditional surveying and documentation methods struggle to keep up. This challenge has pushed the industry toward digital transformation, where the Scan to BIM Workflow plays a central role.

Scan to BIM allows professionals to capture existing conditions exactly as they exist. It converts physical spaces into accurate, data-rich Building Information Models. These models support design decisions, reduce risk, and improve collaboration. Instead of relying on outdated plans or manual measurements, teams work with real-world data.

The Scan to BIM workflow is especially valuable for renovation, retrofit, and facility management projects. In such cases, accurate as-built information often does not exist. Through laser scanning and BIM modeling, stakeholders gain a reliable digital foundation. This blog explains the Scan to BIM workflow in detail, covering every stage from point cloud capture to final model delivery.

1. What Is the Scan to BIM Workflow and How It Works

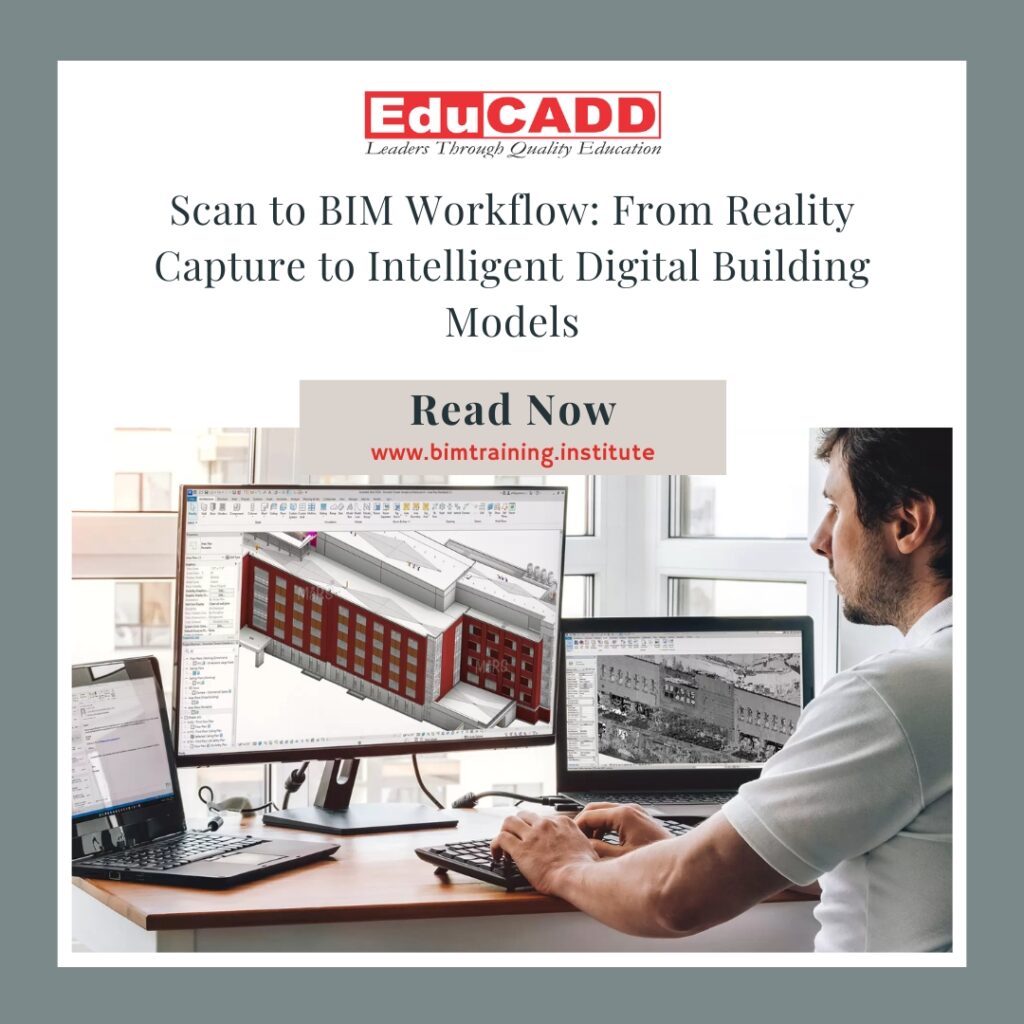

The Scan to BIM Workflow is a structured digital process that transforms physical building data into an intelligent BIM model. It connects reality capture technologies with BIM software to create accurate representations of existing structures.

The workflow begins with on-site data capture using laser scanners or drones. These tools collect millions of spatial data points. The collected data forms a point cloud, which represents the geometry of the building. This point cloud then becomes the reference for BIM modeling.

Unlike traditional drafting methods, Scan to BIM does not depend on interpretation or estimation. Every wall, slab, beam, and service is modeled based on actual site conditions. This reduces uncertainty and increases confidence in project planning.

The workflow follows a logical sequence. Each step depends on the accuracy of the previous one. When teams follow best practices, the Scan to BIM workflow delivers reliable, repeatable results across different project types.

2. Reality Capture: The Foundation of the Scan to BIM Workflow

Reality capture is the most critical stage in the Scan to BIM workflow. The quality of the final BIM model depends heavily on the accuracy of captured data.

Laser scanning, also known as LiDAR, is the most widely used method. Laser scanners emit light pulses that bounce back from surfaces. The scanner calculates distances based on return time. This process generates millions of data points within minutes.

Different scanning methods serve different needs. Terrestrial laser scanners work well for interiors and structural elements. Mobile scanners help capture narrow or complex spaces. Drone-based photogrammetry is ideal for rooftops and large exterior areas.

Planning plays a key role during reality capture. Scan positions must cover all visible surfaces. Overlapping scans help avoid data gaps. Control points improve alignment accuracy. Proper planning ensures a clean and complete dataset for the next stages.

3. Point Cloud Registration and Data Processing

Once scanning is complete, raw scan data moves into processing. This stage transforms individual scans into a unified point cloud.

Each scan exists in its own coordinate system. Registration aligns all scans into a single reference frame. Software tools use targets or natural features to achieve accurate alignment. This step requires careful validation to maintain dimensional accuracy.

Noise removal follows registration. Objects such as people, vehicles, or temporary equipment appear in scans. These elements are removed to improve clarity. Clean point clouds improve modeling speed and reduce interpretation errors.

The processed point cloud represents the real-world geometry of the building. At this point, the Scan to BIM workflow shifts from data preparation to model creation. A high-quality point cloud ensures a smooth transition into BIM software.

4. Optimizing Point Cloud Data for BIM Modeling

Before BIM modeling begins, point cloud data must be optimized. Large datasets can slow down software performance if not managed correctly.

Segmentation helps organize data. The point cloud is divided by floors, zones, or systems. This allows modelers to work efficiently and focus on specific areas. Colorization enhances visual clarity by assigning RGB values to surfaces.

Clipping tools enable sectional views. These views help identify hidden elements such as structural beams, MEP services, and slab thicknesses. Clear visibility supports accurate modeling decisions.

At this stage, project requirements guide the workflow. The required Level of Development (LOD) determines model detail. Clear scope definitions prevent unnecessary modeling and keep the Scan to BIM workflow aligned with project goals.

5. BIM Modeling: Converting Point Clouds into Intelligent Models

BIM modeling is the most detailed phase of the Scan to BIM workflow. Here, point cloud data transforms into intelligent building elements.

Modelers use BIM software such as Revit to trace over the point cloud. Walls, floors, columns, beams, doors, and windows are modeled based on real geometry. Precision is essential at every step.

MEP systems require special attention. Pipes, ducts, cable trays, and equipment are modeled to match existing conditions. Accurate MEP models reduce clashes during renovation or system upgrades.

BIM elements include data, not just geometry. Parameters such as material, size, and system type are embedded. This data supports quantity take-offs, scheduling, and facility management. As a result, the Scan to BIM workflow delivers both visual and functional value.

6. Quality Control, Validation, and Coordination

Quality control ensures the BIM model meets accuracy and project standards. This step protects the integrity of the Scan to BIM workflow.

Model-to-point cloud comparison checks alignment accuracy. Deviations are highlighted and corrected. Tolerance thresholds vary based on project requirements.

Coordination reviews identify clashes between disciplines. Architectural, structural, and MEP models are reviewed together. Early clash detection saves time and reduces construction risk.

Documentation standards also matter. Naming conventions, parameter consistency, and file organization improve usability. A validated model becomes a trusted reference for all stakeholders.

7. Use Cases and Advantages of the Scan to BIM Workflow

The Scan to BIM workflow supports a wide range of applications. Renovation projects benefit from accurate existing-condition models. Designers can plan modifications with confidence.

Facility managers use BIM models for asset tracking, maintenance planning, and space management. Accurate models improve operational efficiency over the building lifecycle.

Heritage conservation projects rely on Scan to BIM for preserving complex structures. Detailed digital records protect historical assets without physical intervention.

The workflow also improves collaboration. Teams work from a shared data source. Errors reduce, coordination improves, and project timelines shorten. These advantages make Scan to BIM a strategic investment for modern construction.

Conclusion

The Scan to BIM Workflow has redefined how existing buildings are documented and managed. It replaces assumptions with verified data and manual surveys with digital precision.

From reality capture to intelligent BIM modeling, each stage plays a vital role. When executed correctly, the workflow delivers accurate, reliable, and data-rich models that support the entire building lifecycle.

As technology advances, Scan to BIM will continue to evolve. Integration with automation, digital twins, and smart building systems will unlock even greater value.

For organizations focused on quality, efficiency, and long-term performance, adopting the Scan to BIM workflow is no longer optional. It is a foundation for the future of digital construction.