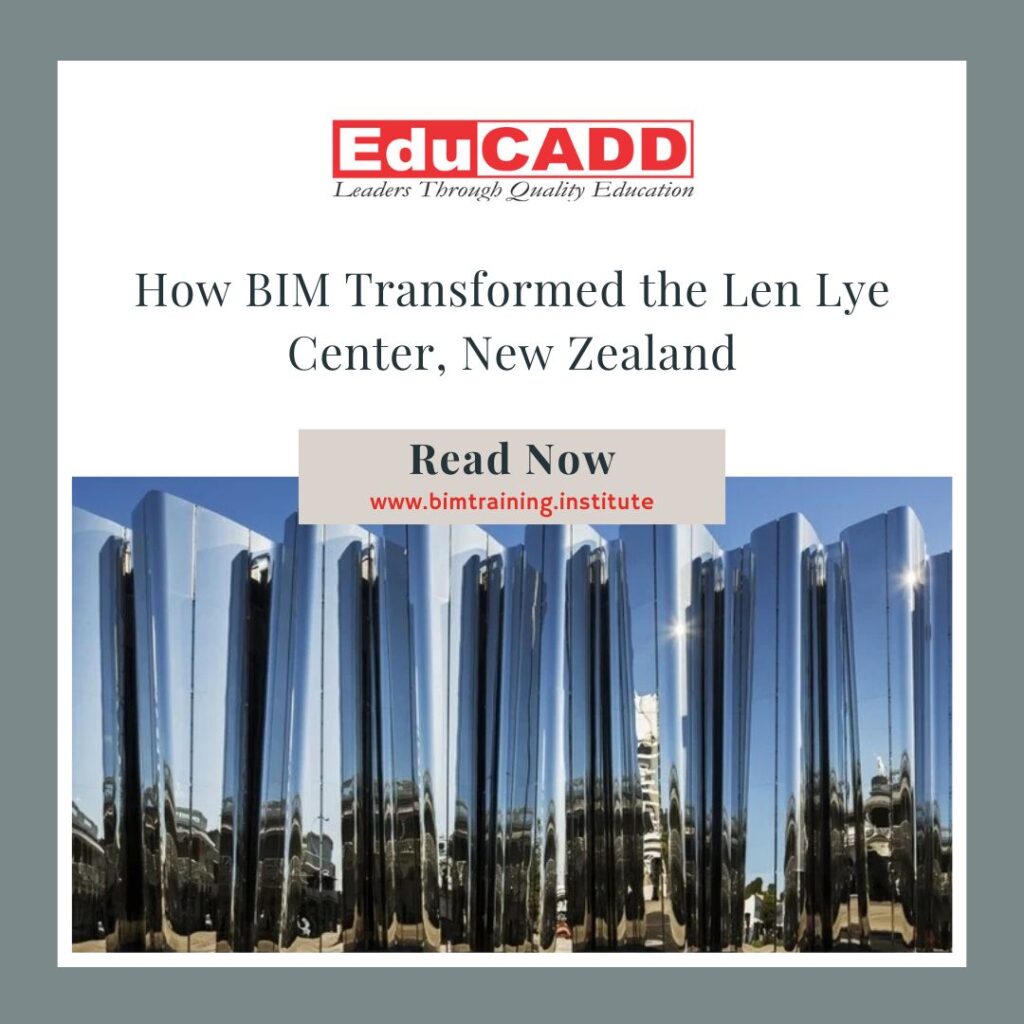

The Len Lye Center in New Plymouth, New Zealand, is one of the most striking architectural landmarks in the country. Dedicated to the famous experimental filmmaker and kinetic sculptor Len Lye, the museum is celebrated not only for its cultural significance but also for its complex design and construction process—made possible through Building Information Modeling (BIM).

About the Project

- Location: New Plymouth, New Zealand

- Opened: 2015

- Architects: Patterson Associates

- Function: Museum and cultural center

- Highlight: Stainless steel façade with mirrored panels, creating a highly reflective surface

The design of the Len Lye Center pushed traditional construction boundaries, especially with its curved stainless-steel façade and complex structural alignments. This required precise planning, digital collaboration, and advanced coordination tools, where BIM became the backbone of execution.

Role of BIM in the Len Lye Center

1. Complex Geometry & Design Visualization

The reflective stainless-steel façade of the Len Lye Center was unlike anything built before in New Zealand. BIM allowed the design team to:

- Accurately model the curved façade panels in 3D.

- Simulate how reflections and light would behave across surfaces.

- Ensure constructability before physical work began.

Without BIM, creating such a precise and dynamic surface would have been nearly impossible.

2. Clash Detection & Coordination

The building’s structure integrated steel, glass, and reinforced concrete, requiring multiple disciplines—architecture, structural, and mechanical systems—to work together.

- BIM’s clash detection in tools like Navisworks helped identify conflicts early.

- The process minimized costly rework on site.

- Enabled a smoother integration of HVAC, lighting, and service routes into the design.

3. Prefabrication & Accuracy

The façade panels and structural elements were prefabricated based on BIM models.

- Every piece was digitally tested for fit and alignment.

- Prefabrication reduced waste, construction time, and cost overruns.

- Contractors had precise installation guidance directly from BIM outputs.

4. Collaboration Between Teams

As a high-profile cultural project, multiple stakeholders were involved—architects, contractors, fabricators, and city authorities. BIM provided a Common Data Environment (CDE) where:

- All teams accessed the latest models and revisions.

- Communication errors were reduced.

- Decision-making became faster and more transparent.

5. Long-Term Facility Management

BIM didn’t just stop at construction—it continues to benefit the facility managers of the Len Lye Center.

- The as-built BIM model serves as a reference for maintenance.

- Data on materials, structural systems, and service equipment is stored digitally.

- This supports sustainability and reduces future operational costs.

Why This Project Matters

The Len Lye Center is a landmark example of BIM in New Zealand. It showcases how BIM is not just a design tool, but a holistic approach to construction and building lifecycle management.

- It demonstrated the feasibility of using BIM for complex geometry and artistic architecture.

- The project set a new benchmark for cultural infrastructure in New Zealand.

- It highlighted the cost-saving and time-saving advantages of BIM adoption.

Final Thoughts

The Len Lye Center stands as proof that BIM can turn ambitious architectural visions into reality. For architects, engineers, and builders, it serves as an inspiring case study in how digital tools can bridge the gap between creativity and constructability.

As BIM adoption grows globally, projects like the Len Lye Center remind us that technology and artistry can coexist to create timeless structures.