Introduction

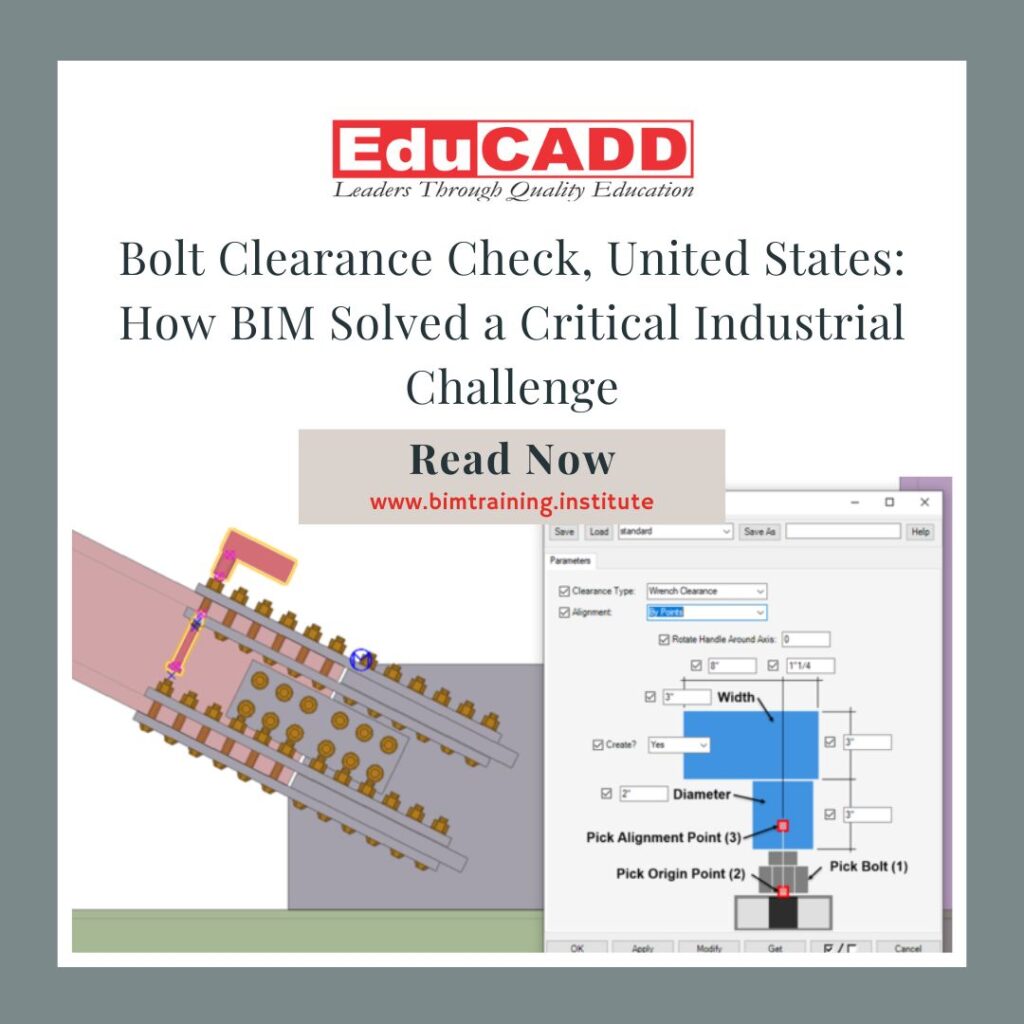

In industrial projects, even the smallest details can lead to massive delays and costly rework. One such challenge is bolt clearance, where bolts, nuts, and fasteners may not fit properly in tight spaces during assembly. Traditionally, this issue was discovered on-site, causing redesigns, downtime, and extra costs.

The Bolt Clearance Check project in the United States is a prime example of how Building Information Modeling (BIM) helped engineers solve this problem digitally before construction began. This case study highlights the importance of BIM in industrial detailing, fabrication, and assembly accuracy.

The Problem: Why Bolt Clearance Matters

- Precision requirement: In industries such as oil & gas, power plants, and heavy machinery, equipment requires exact alignment. Even a few millimeters of error in bolt placement can cause serious problems.

- Traditional risks: Without digital checks, bolt clearance issues were often discovered only at the installation stage. This led to:

- Re-drilling holes

- Redesigning steel structures

- Delays in project delivery

- Wasted resources and higher costs

How BIM Was Used in Bolt Clearance Check

1. 3D Modeling of Bolts and Connections

Instead of generic placeholders, BIM software created highly detailed 3D models of bolts, nuts, washers, and plates. This allowed engineers to test every connection virtually before fabrication.

2. Tolerance and Clearance Analysis

BIM was used to check:

- Whether bolts could be tightened in confined spaces

- If tools like wrenches could fit around the bolts

- Minimum spacing required for safe installation

3. Clash Detection

BIM’s clash detection tools highlighted conflicts between bolts, surrounding steel members, and equipment. This ensured all adjustments were made digitally, preventing on-site issues.

4. Fabrication Accuracy

The BIM model was directly linked with fabrication drawings. This improved accuracy in steel cutting, hole drilling, and bolt placement, reducing manual errors.

5. 4D Construction Simulation

BIM also simulated the sequence of assembly, ensuring that bolts and connections could be installed in the right order without obstructions.

Benefits Achieved

- Zero on-site rework related to bolt clearance

- Significant cost savings by avoiding fabrication mistakes

- Faster assembly with ready-to-fit parts

- Improved worker safety by eliminating the need for re-drilling or unsafe adjustments

- Higher client confidence due to accuracy and predictability

Industry Impact

The Bolt Clearance Check case study demonstrates that BIM is not only for buildings and skyscrapers but is equally crucial for industrial, mechanical, and structural projects. From steel bridges to oil refineries, BIM helps ensure precision in detailing—reducing errors that could otherwise cost millions.

Conclusion

The Bolt Clearance Check project in the United States proved that BIM can detect and resolve microscopic design challenges before they become massive on-site problems. By combining detailed 3D modeling, clash detection, and fabrication integration, BIM provided a reliable and cost-effective solution that is now being adopted across industrial sectors worldwide.