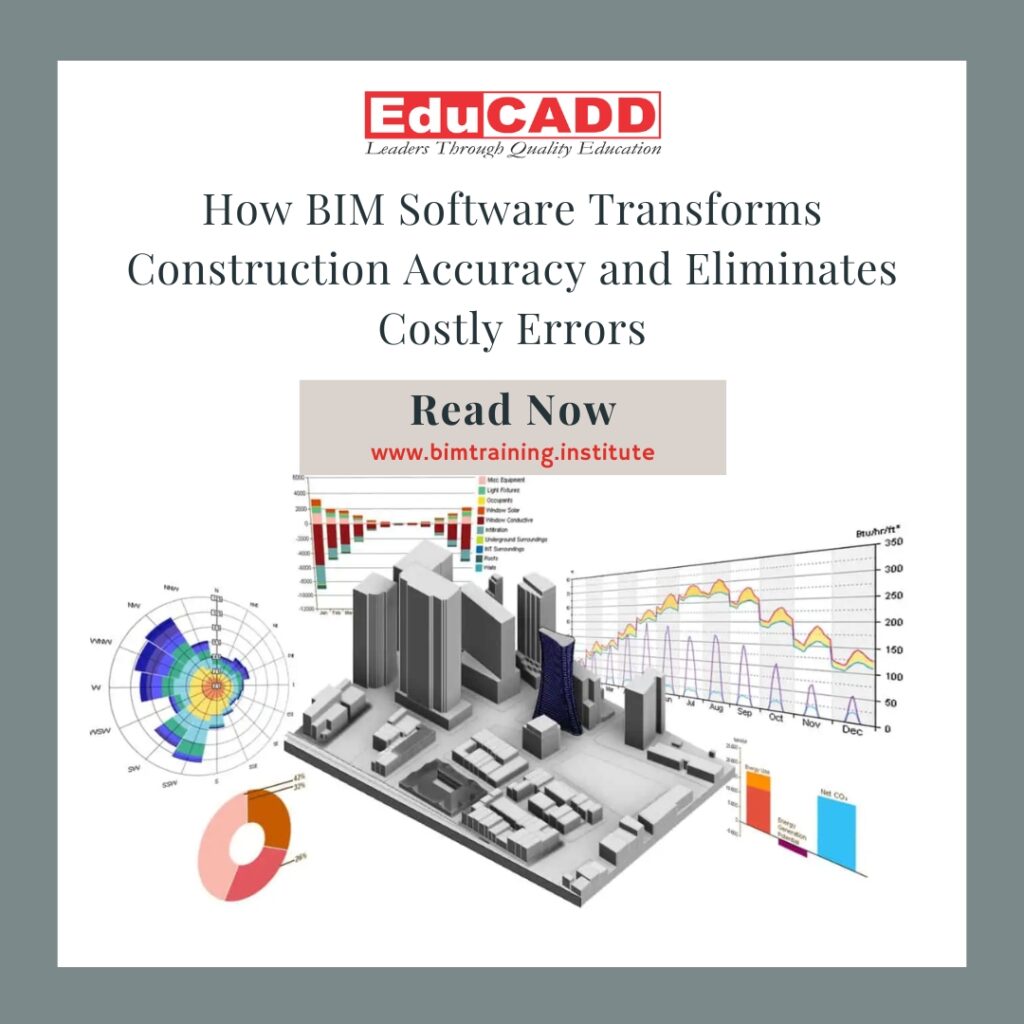

Construction errors continue to challenge the global construction industry despite advances in materials, engineering methods, and project controls. Design inconsistencies, coordination gaps, inaccurate drawings, and poor communication frequently lead to rework, delays, disputes, and cost overruns. Even small errors can escalate into major project failures when discovered late on site. As construction projects grow more complex, traditional 2D workflows struggle to manage interdependencies across disciplines. This is where BIM Software Construction Accuracy has emerged as a game-changing solution. By integrating data, geometry, and collaboration into a single intelligent model, BIM software fundamentally changes how teams plan, design, build, and manage construction projects. Most importantly, it dramatically reduces construction errors at every stage of the project lifecycle.

1. Understanding the Root Causes of Construction Errors

Before examining how BIM Software Construction Accuracy reduces errors, it is important to understand why those errors occur in the first place. Most construction mistakes arise from fragmented workflows, disconnected teams, and incomplete information. Architects, engineers, contractors, and consultants often work in silos, using separate drawings and documents that rarely align perfectly. Misinterpretation of drawings, outdated revisions, and missing details lead to clashes and inaccuracies on site. Human error also increases when teams manually coordinate thousands of components under tight deadlines. BIM software addresses these root causes by replacing fragmented processes with a centralized, data-driven environment where all stakeholders work from a shared source of truth.

2. Centralized Digital Models Improve Design Accuracy

One of the most powerful ways BIM software reduces construction errors is through centralized digital modeling. Instead of relying on multiple disconnected drawings, teams develop a single coordinated 3D model that contains architectural, structural, and MEP elements. Every wall, beam, pipe, and cable exists within the same environment. When designers modify one element, the change updates automatically across all views and schedules. This real-time coordination eliminates discrepancies between plans, sections, and elevations. As a result, teams detect design issues early, long before they reach the construction site, where corrections become far more expensive.

3. Clash Detection Prevents On-Site Conflicts

Clashes between building systems represent one of the most common and costly construction errors. For example, a duct may intersect with a beam, or plumbing lines may interfere with electrical conduits. Traditional workflows often detect these conflicts only during installation. BIM software uses automated clash detection tools to identify conflicts digitally during the design phase. Teams can run coordination checks across disciplines and resolve issues collaboratively. By addressing clashes before construction begins, BIM software prevents rework, reduces material waste, and avoids schedule disruptions that typically result from late-stage corrections.

4. Enhanced Visualization Improves Decision-Making

Construction errors frequently occur because stakeholders struggle to visualize complex designs using 2D drawings. BIM software provides immersive 3D visualization that allows teams to see the building exactly as it will be constructed. Clients, contractors, and consultants can explore spaces, systems, and sequences in detail. This clarity improves understanding and reduces assumptions. When stakeholders fully comprehend the design intent, they make better decisions and identify potential issues earlier. Improved visualization also minimizes miscommunication between technical teams and non-technical stakeholders, which further reduces the risk of costly mistakes.

5. Accurate Quantity Takeoffs Reduce Material Errors

Inaccurate quantity estimation often leads to shortages, overordering, or incorrect material usage. BIM software links model elements directly to quantity takeoffs and cost data. Because quantities derive from actual model geometry, estimates remain more accurate and reliable. When design changes occur, quantities update automatically, preventing outdated calculations. This accuracy reduces procurement errors and ensures materials match design specifications. As a result, contractors avoid delays caused by missing components or incorrect deliveries, which frequently disrupt construction workflows.

6. Improved Coordination Between Multidisciplinary Teams

Construction projects involve numerous disciplines working simultaneously. Without proper coordination, even minor misalignments can cause serious errors. BIM Software Construction Accuracy fosters collaboration by allowing all teams to work within a shared digital environment. Cloud-based BIM platforms enable real-time access to models, updates, and comments. Teams can review changes, raise issues, and resolve conflicts collaboratively. This transparency reduces misunderstandings and ensures everyone works with the latest information. Strong coordination through BIM software significantly lowers the risk of errors caused by outdated or incomplete data.

7. Construction Sequencing with 4D BIM

Errors often arise when construction activities follow inefficient or conflicting sequences. BIM software supports 4D modeling, which links the 3D model with the project schedule. This capability allows teams to simulate construction sequences visually over time. By analyzing the sequence, teams can identify logistical conflicts, access issues, and scheduling risks before construction begins. Contractors can optimize workflows, reduce congestion on site, and avoid errors caused by poor planning. 4D BIM improves predictability and ensures construction progresses logically and safely.

8. Reduced Rework Through Early Error Detection

Rework represents one of the most significant cost drivers in construction projects. Fixing errors after installation consumes time, labor, and materials. BIM software dramatically reduces rework by enabling early detection of issues during design and preconstruction. When teams identify problems digitally, corrections require minimal effort compared to physical changes on site. Early error detection also improves quality outcomes, as teams can refine details and specifications proactively. Over time, reduced rework leads to substantial savings and improved project performance.

9. Standardization and Consistency Across Documentation

Inconsistent documentation often leads to confusion and construction errors. BIM software generates drawings, schedules, and reports directly from the model. Because all documents derive from the same source, consistency improves across the entire project. Changes made in the model automatically reflect in every output, reducing the risk of conflicting information. This standardization ensures contractors receive clear, accurate instructions, which minimizes interpretation errors during construction.

10. Better Communication Between Design and Site Teams

Communication gaps between office teams and site personnel frequently result in execution errors. BIM software bridges this gap by providing site teams with access to digital models through tablets or mobile devices. Workers can view updated drawings, details, and annotations directly on site. This access reduces reliance on printed drawings that may become outdated. Clear communication through BIM software ensures site teams execute work accurately according to the latest design intent.

11. Improved Quality Control and Compliance

Maintaining quality and regulatory compliance requires precise documentation and verification. BIM software supports quality control by embedding specifications, codes, and standards within the model. Teams can verify compliance digitally and ensure installations meet required criteria. Inspection processes become more efficient when inspectors can reference accurate models. This proactive approach reduces errors related to non-compliance and improves overall construction quality.

12. Risk Reduction Through Data-Driven Insights

Construction errors often stem from uncertainty and lack of foresight. BIM software generates valuable data that supports informed decision-making. By analyzing models, teams can assess risks related to constructability, safety, and performance. Predictive insights help teams address vulnerabilities before they escalate into errors. Data-driven planning strengthens risk management and enhances project reliability.

13. Lifecycle Benefits Beyond Construction

The error-reducing benefits of BIM software extend beyond construction into facility management and operations. Accurate as-built models provide reliable information for maintenance, renovations, and future upgrades. When facility managers trust the data, they avoid errors related to unknown conditions or inaccurate documentation. BIM software therefore delivers long-term value by reducing operational risks and improving asset performance throughout the building lifecycle.

14. Cultural Shift Toward Proactive Problem Solving

Beyond technology, BIM software promotes a cultural shift within project teams. Instead of reacting to problems on site, teams adopt a proactive mindset focused on prevention. Collaborative workflows encourage early engagement and shared responsibility for accuracy. This cultural transformation reduces blame, improves accountability, and fosters continuous improvement. As teams gain experience with BIM software, error reduction becomes an integral part of their project delivery approach.

Conclusion

Construction errors are not inevitable. They result from outdated processes, fragmented communication, and limited visibility. BIM Software Construction Accuracy addresses these challenges by integrating design, data, and collaboration into a unified digital workflow. From clash detection and visualization to accurate quantities and construction sequencing, BIM software reduces errors at every stage of the project lifecycle. By enabling early detection, improving coordination, and supporting informed decision-making, it transforms how construction teams deliver projects. Organizations that adopt BIM software not only reduce costly mistakes but also achieve higher quality, greater efficiency, and long-term project success.