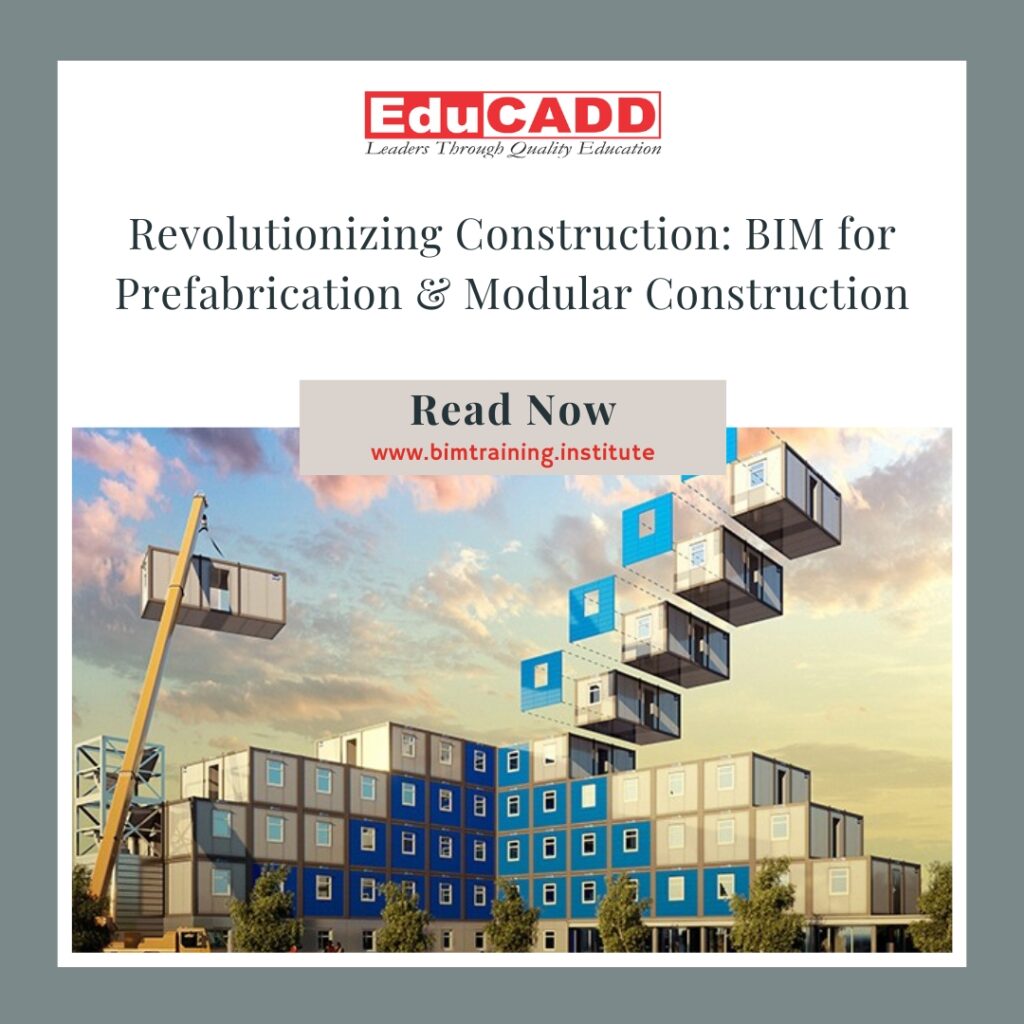

The construction industry is undergoing a massive transformation. With increasing demand for faster, more cost-effective, and sustainable building solutions, traditional construction methods are being challenged. BIM Prefabrication Modular Construction has emerged as a game-changer, especially when integrated with prefabrication and modular construction. These methods allow precise planning, reduced waste, and faster execution. This blog explores how BIM revolutionizes prefabrication and modular construction, enhancing efficiency, collaboration, and innovation across the entire project lifecycle.

Understanding BIM in Modern Construction

BIM, or Building Information Modeling, is a digital representation of a building’s physical and functional characteristics. It is more than a 3D model—it is a collaborative platform that allows architects, engineers, contractors, and owners to work together seamlessly. By incorporating prefabrication and modular construction processes into BIM, construction teams can visualize components before they reach the site. This level of precision reduces errors, avoids costly delays, and ensures a high-quality final product.

BIM also supports real-time data updates. Any design change immediately reflects across all project disciplines. This capability is especially critical in modular construction, where components are fabricated offsite. Prefabrication relies heavily on precise measurements and accurate scheduling. Integrating BIM ensures that every piece, from walls to mechanical systems, fits perfectly, reducing the risk of rework.

The Rise of Prefabrication and Modular Construction

Prefabrication and modular construction are no longer niche trends—they are the future of building. Prefabrication involves creating building components offsite in a controlled environment. Modular construction takes this further by assembling entire modules offsite, which are then transported and installed at the construction site. These methods accelerate project timelines, minimize site disruption, and enhance sustainability by reducing waste.

Combining these techniques with BIM magnifies their benefits. BIM models provide a digital twin of every module and component, allowing for precise planning and error detection. Construction teams can identify potential clashes between structural, mechanical, and electrical systems before fabrication begins. This integration results in higher efficiency, reduced costs, and improved safety standards.

How BIM Improves Design Accuracy

One of the most significant advantages of BIM in prefabrication and modular construction is design accuracy. Traditional construction relies heavily on 2D drawings, which can lead to misinterpretation. BIM, however, enables a 3D representation, providing a clear and accurate visualization of every element.

Designers can simulate the construction process, check tolerances, and ensure that prefabricated components fit perfectly. For example, BIM allows structural engineers to assess load distribution within modular units, ensuring stability and compliance with building codes. By reducing design errors, BIM prevents costly delays and ensures that prefabricated modules arrive onsite ready for assembly.

Enhanced Collaboration Across Teams

BIM fosters seamless collaboration among architects, engineers, fabricators, and contractors. In modular construction, teams often work from different locations, making coordination challenging. BIM provides a shared platform where every stakeholder can access the latest design and schedule information.

This level of collaboration prevents miscommunication and ensures that every team member works with accurate, real-time data. Fabricators can adjust production schedules based on updates from architects or structural engineers. Contractors can plan site logistics more effectively, knowing the exact arrival times of modular components. The result is a smoother construction process and a high-quality finished structure.

Clash Detection and Risk Mitigation

In traditional construction, conflicts between structural, mechanical, and electrical systems often become apparent only during installation, causing costly delays. BIM’s clash detection feature identifies these conflicts in the digital model before fabrication or assembly.

In prefabricated and modular construction, this capability is crucial. Each module is manufactured offsite with tight tolerances. Any design clash can disrupt the entire assembly process. BIM reduces these risks by simulating every connection, joint, and interface in advance. This proactive approach not only saves time but also reduces material waste and increases project predictability.

Accelerating Project Timelines

Time efficiency is one of the primary reasons why prefabrication and modular construction are gaining popularity. When combined with BIM, project timelines shorten significantly. BIM allows simultaneous design, fabrication, and construction planning.

For example, while architects finalize the design of upcoming modules, fabricators can start producing initial components using BIM models. This parallel workflow reduces idle time and accelerates project completion. On-site assembly becomes faster as each module arrives ready to install, eliminating traditional delays caused by material shortages, design errors, or coordination gaps.

Cost Optimization with BIM

Construction budgets often spiral due to unforeseen errors, material wastage, and extended timelines. BIM addresses these challenges by providing precise material quantities, identifying clashes early, and streamlining workflows.

In prefabrication and modular construction, cost predictability improves dramatically. Each module’s design and assembly are digitally pre-planned, minimizing the risk of errors that lead to rework. Furthermore, BIM allows cost simulation, enabling stakeholders to assess the financial impact of design choices. This level of transparency ensures better budgeting and resource allocation throughout the project lifecycle.

Sustainability and Waste Reduction

Sustainability is a growing concern in the construction industry. Prefabrication and modular construction already reduce environmental impact by optimizing material usage and minimizing site waste. BIM enhances sustainability further.

By digitally modeling each component, BIM ensures that materials are used efficiently and only as required. Modules can be fabricated with minimal offcuts, and construction waste is significantly reduced. Additionally, BIM allows simulation of energy performance, helping architects design modules that meet sustainability standards and reduce long-term operational costs.

Integration with Advanced Manufacturing

Modern construction increasingly incorporates advanced manufacturing techniques, including robotics, CNC machines, and automated assembly lines. BIM seamlessly integrates with these technologies, ensuring that prefabricated components are fabricated to exact specifications.

By linking BIM models with automated machinery, construction teams can achieve unparalleled precision. Components are manufactured with millimeter accuracy, reducing errors and improving fit during onsite assembly. This synergy between digital planning and advanced manufacturing ensures higher quality construction while reducing labor costs and time.

Real-Time Progress Monitoring

BIM is not limited to design and fabrication—it also enables real-time monitoring of construction progress. Project managers can track the status of prefabricated modules, monitor delivery schedules, and ensure on-site assembly aligns with the project plan.

In modular construction, this visibility is critical. Delays in one module can affect the entire project timeline. BIM allows teams to proactively adjust schedules, reroute resources, and address potential bottlenecks before they escalate. This real-time insight ensures projects stay on track, reducing delays and improving client satisfaction.

Enhancing Safety Standards

Construction safety is paramount. Prefabrication and modular construction already reduce onsite hazards by limiting the number of workers and time spent at the site. BIM further enhances safety by simulating construction sequences and identifying potential risks.

BIM allows safety engineers to plan crane operations, module installations, and worker movements in a virtual environment. This pre-planning reduces onsite accidents, ensures compliance with safety regulations, and provides a safer environment for all construction personnel.

Improving Quality Control

Quality control is significantly enhanced through BIM integration. Every prefabricated component is digitally verified against the model before leaving the factory. This ensures that each module meets design specifications and maintains uniform quality.

During onsite assembly, BIM models serve as reference points, ensuring accurate installation. Any deviation can be immediately corrected, preventing structural or functional issues. This continuous monitoring and verification process guarantees superior construction quality and long-lasting durability of prefabricated and modular buildings.

BIM and Lifecycle Management

The benefits of BIM extend beyond construction. Once a modular building is complete, BIM serves as a valuable tool for facility management. The digital model contains detailed information about every component, including maintenance schedules, warranties, and specifications.

Facility managers can use BIM to plan renovations, replace faulty components, and monitor building performance. In prefabricated and modular construction, where components are standardized, BIM simplifies lifecycle management, reducing maintenance costs and prolonging the building’s service life.

Future Trends in BIM and Modular Construction

The future of construction lies in the synergy between BIM, prefabrication, and modular construction. Emerging technologies such as AI, IoT, and AR/VR are increasingly integrated with BIM, allowing predictive modeling, automated quality checks, and immersive visualization.

Robotics and automation will further streamline prefabrication, while BIM ensures precise coordination across every stage. Modular construction will continue to grow as urbanization increases, and BIM will remain central to achieving faster, safer, and more sustainable buildings.

Conclusion

BIM Prefabrication Modular Construction, bringing unprecedented accuracy, collaboration, and efficiency. By integrating digital modeling with offsite fabrication, construction teams can reduce costs, accelerate timelines, enhance sustainability, and improve safety.

As the industry evolves, embracing BIM in modular construction will no longer be optional—it will be essential. Stakeholders who adopt this approach can achieve higher-quality buildings, faster delivery, and long-term value, marking a new era in construction innovation.