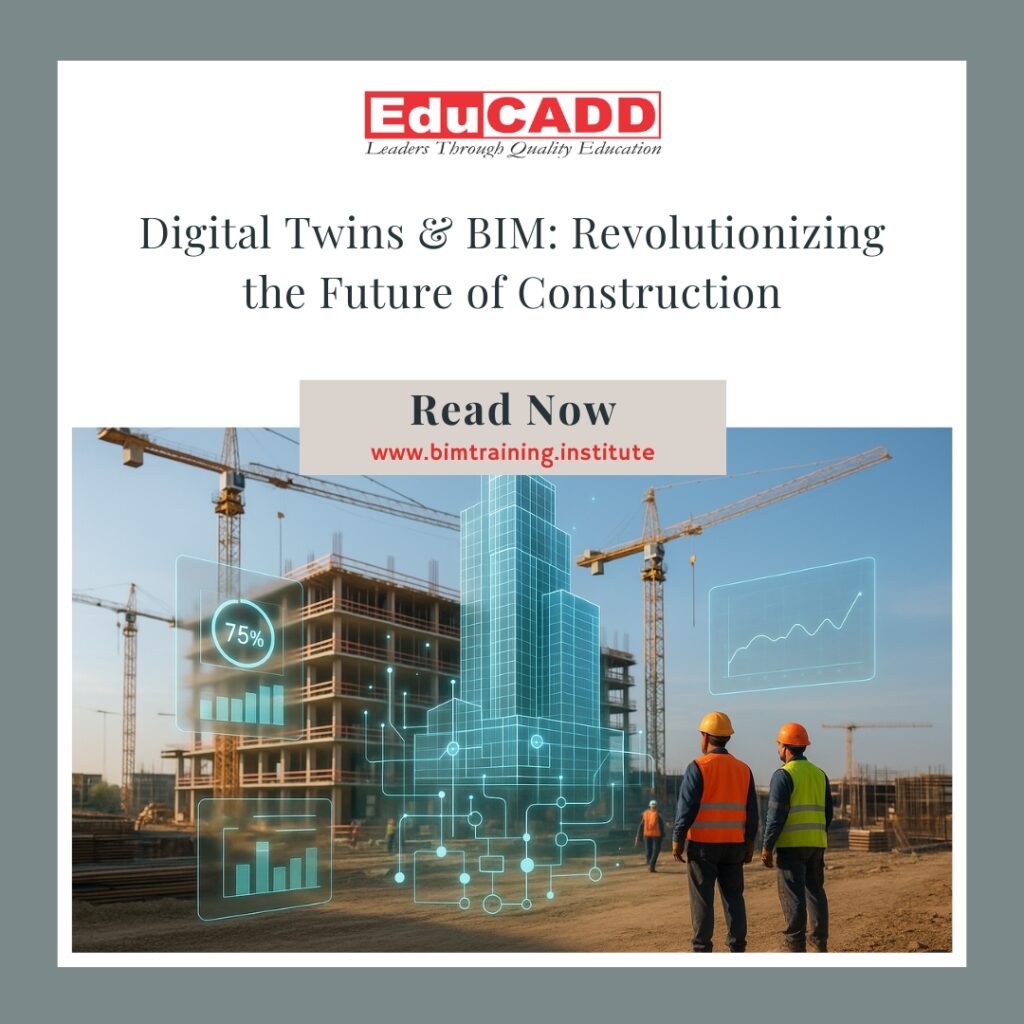

Digital Twins & BIM: Revolutionizing the Future of Construction

The construction industry has traditionally relied on conventional methods for planning, design, and execution. However, with rapid technological advancements, Digital Twins BIM Construction have emerged as transformative tools, redefining how projects are conceived, managed, and maintained. Digital Twins, virtual replicas of physical assets, enable real-time monitoring, predictive analysis, and data-driven decision-making. Meanwhile, BIM facilitates collaborative design and integrated workflows among architects, engineers, and contractors. Together, these technologies promise a future where construction projects are safer, more efficient, and more sustainable. This blog explores the critical role of Digital Twins and BIM in modern construction, highlighting their benefits, applications, and potential to reshape the industry.

1. Understanding Digital Twins in Construction

Digital Twins are virtual models of physical structures, systems, or processes that replicate real-world conditions in a digital environment. By integrating data from sensors, IoT devices, and project management tools, Digital Twins provide continuous insights into the health and performance of construction projects. These digital replicas allow stakeholders to anticipate potential issues, optimize workflows, and enhance decision-making. The ability to simulate real-world scenarios in a controlled digital space ensures better accuracy, reduces risks, and saves both time and costs during construction and operation.

2. BIM: The Backbone of Collaborative Design

Building Information Modeling (BIM) is a methodology that allows construction professionals to create detailed digital representations of buildings. Unlike traditional CAD, BIM incorporates geometry, spatial relationships, geographic information, quantities, and properties of building components. This holistic approach ensures that all stakeholders, from architects to contractors, work on the same platform, minimizing errors and improving coordination. BIM also facilitates clash detection, resource planning, and lifecycle management, making it indispensable in modern construction projects.

3. Integration of Digital Twins and BIM

The real power of these technologies emerges when Digital Twins and BIM are integrated. While BIM focuses on design and pre-construction planning, Digital Twins extend this capability into the construction and operational phases. Combining both technologies creates a continuous loop of data-driven insights, enabling proactive maintenance, performance optimization, and risk management. This integration ensures that construction projects are not only built efficiently but also perform optimally throughout their lifecycle.

4. Enhancing Project Planning and Scheduling

One of the primary benefits of Digital Twins and BIM is enhanced project planning and scheduling. Using BIM, project managers can simulate construction sequences and identify potential delays before breaking ground. Digital Twins complement this by monitoring real-time progress on-site, providing predictive analytics, and enabling proactive interventions. This combination reduces delays, prevents cost overruns, and ensures that projects remain on track.

5. Improving Cost Efficiency

Cost management is a persistent challenge in construction. BIM allows detailed cost estimation during the design phase, while Digital Twins track resource utilization and operational efficiency in real-time. This dual approach minimizes waste, optimizes material usage, and reduces unforeseen expenses. By integrating predictive analytics, construction teams can make informed decisions, ensuring that projects stay within budget without compromising quality.

6. Enhancing Safety and Risk Management

Construction sites are inherently risky, with safety being a paramount concern. Digital Twins enable real-time monitoring of site conditions, identifying hazards before they escalate into accidents. BIM assists in designing safer structures by evaluating spatial layouts, emergency exits, and compliance with safety standards. Together, these technologies foster a culture of safety, reducing incidents and ensuring regulatory compliance.

7. Streamlining Maintenance and Facility Management

The benefits of Digital Twins extend beyond construction into the operation and maintenance of buildings. With Digital Twins, facility managers can monitor equipment performance, predict failures, and schedule maintenance proactively. BIM provides a detailed inventory of building components, simplifying repairs and upgrades. This predictive maintenance approach increases asset longevity, reduces downtime, and ensures operational efficiency throughout the building’s lifecycle.

8. Promoting Sustainability in Construction

Sustainability is increasingly becoming a central focus in construction. BIM allows precise material quantification and waste reduction, while Digital Twins enable monitoring of energy consumption, carbon emissions, and water usage in real-time. By simulating environmental impacts before construction begins, these technologies help design eco-friendly structures, reduce resource wastage, and support green building certifications.

9. Facilitating Data-Driven Decision Making

In modern construction, decisions must be backed by accurate data. Digital Twins provide continuous real-time data streams, while BIM consolidates historical and design-related information. This combination enables construction teams to make informed decisions, anticipate challenges, and optimize workflows. Data-driven approaches enhance productivity, reduce risks, and improve overall project quality.

10. Enhancing Collaboration Among Stakeholders

Large construction projects involve multiple stakeholders with diverse responsibilities. BIM fosters collaboration by providing a centralized digital environment for design, documentation, and communication. Digital Twins extend this collaboration to the operational phase, allowing stakeholders to monitor performance and resolve issues in real-time. This seamless interaction minimizes misunderstandings, ensures accountability, and improves project outcomes.

11. Case Studies of Successful Implementation

Several construction projects worldwide have demonstrated the effectiveness of Digital Twins and BIM integration. For example, smart infrastructure projects in Singapore utilize Digital Twins to monitor traffic flow, structural health, and maintenance needs. Similarly, BIM-enabled projects in Europe have reduced project delays by up to 30% through clash detection and precise planning. These examples highlight how these technologies are not just futuristic concepts but practical tools driving efficiency in real-world construction.

12. Overcoming Challenges in Adoption

Despite their benefits, integrating Digital Twins and BIM presents challenges. High initial costs, the need for skilled personnel, and data management complexities can hinder adoption. However, advancements in software, cloud computing, and training programs are gradually overcoming these barriers. Companies investing in digital transformation today will gain a competitive edge in the rapidly evolving construction landscape.

13. Future Trends in Construction Technology

The future of construction is digital, and Digital Twins and BIM are central to this transformation. Emerging trends include the use of AI for predictive analytics, IoT-enabled sensor networks for real-time monitoring, and augmented reality for immersive visualization. As these technologies evolve, construction projects will become smarter, safer, and more sustainable, enabling industry leaders to achieve unprecedented efficiency and innovation.

14. Preparing the Workforce for Digital Transformation

The shift toward Digital Twins and BIM requires a skilled workforce. Professionals must be trained in digital modeling, data analytics, and virtual collaboration. Educational institutions and training centers are increasingly offering courses tailored to these technologies. A digitally competent workforce ensures that organizations can fully leverage these tools, enhancing productivity and fostering innovation in the construction sector.

Conclusion

Digital Twins BIM Construction are not just technological advancements—they are catalysts for a new era in construction. By bridging the gap between design, construction, and operations, these tools ensure projects are efficient, sustainable, and safer. Organizations that embrace this digital transformation can reduce costs, improve collaboration, and make informed decisions based on real-time insights. As the construction industry continues to evolve, the integration of Digital Twins and BIM will define the future, creating smarter buildings and resilient infrastructure for generations to come.